High-Efficiency Industrial Dehumidification & Cooling — Reinvented by TRIGeN DC

Desiccant Based Cooling Solutions

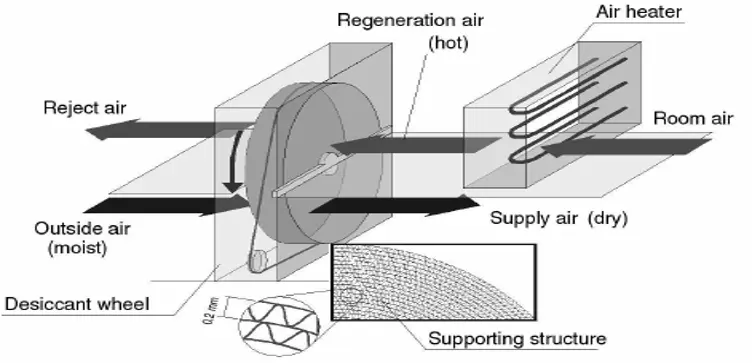

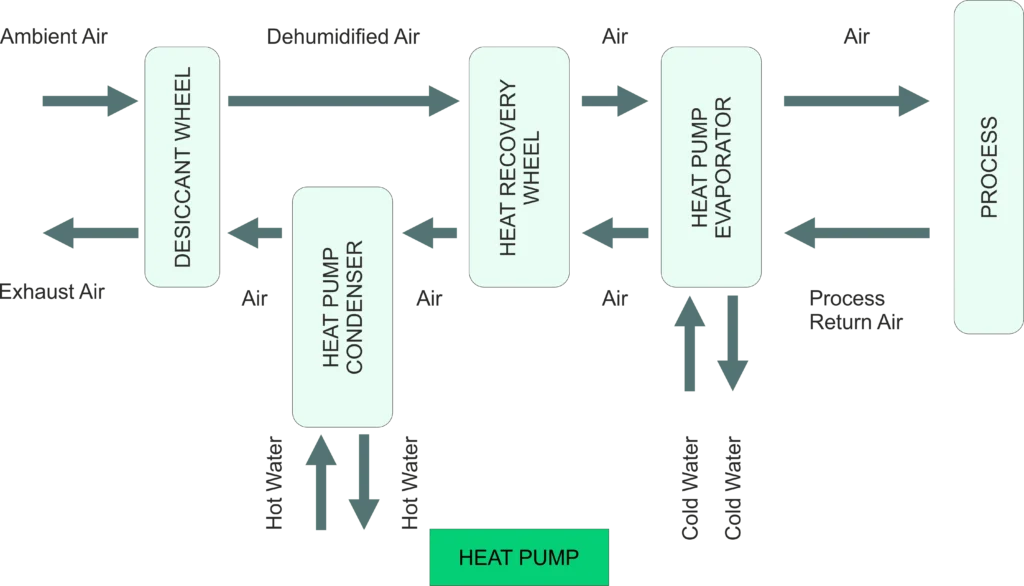

Desiccant-Based Cooling Solutions are advanced industrial systems designed to control humidity and provide efficient cooling by using high-performance desiccant materials instead of traditional silica-gel beds.

These systems work by absorption excess moisture from the air and regenerating at remarkably low temperatures – around 70°C, making them far more energy-efficient than legacy silica-gel technologies that require 120-140°C regeneration.

TRIGeN DC’s next-generation desiccant systems deliver over 80% moisture absorption, faster regeneration cycles, seamless heat pump compatibility, and long operational life. This ensures stable humidity control, reduced energy consumption, and high-performance cooling across industrial, commercial, and cleanroom environments. Built for 24×7 duty, these solutions provide a sustainable, cost-effective upgrade for industries demanding precision, efficiency, and reliability.

Desiccant Based Cooling Solutions

Desiccant-Based Cooling Solutions are advanced industrial systems designed to control humidity and provide efficient cooling by using high-performance desiccant materials instead of traditional silica-gel beds.

These systems work by absorption excess moisture from the air and regenerating at remarkably low temperatures – around 70°C, making them far more energy-efficient than legacy silica-gel technologies that require 120-140°C regeneration.

TRIGeN DC’s next-generation desiccant systems deliver over 80% moisture absorption, faster regeneration cycles, seamless heat pump compatibility, and long operational life. This ensures stable humidity control, reduced energy consumption, and high-performance cooling across industrial, commercial, and cleanroom environments. Built for 24×7 duty, these solutions provide a sustainable, cost-effective upgrade for industries demanding precision, efficiency, and reliability.

Modern industries have a high demand for precise humidity control, stable cooling, and low-energy operation to ensure product quality, operational reliability, and worker comfort.

Traditional dehumidification systems, especially silica-gel-based solutions, are energy-intensive, slow to regenerate, and expensive to maintain — making them unsuitable for today’s efficiency-driven and sustainability-focused manufacturing environments.

TRIGeN DC’s Desiccant-Based Cooling Solutions are engineered to overcome these limitations. Designed as a next-generation replacement for silica-gel beds, these systems deliver superior moisture absorption, ultra-low regeneration energy, long service life, and seamless compatibility with high-efficiency heat pumps. The result is a powerful, eco-friendly dehumidification technology built for continuous industrial duty.

With >80% moisture absorption capacity, low-temperature regeneration at ~70°C, and up to 25% reduction in carbon emissions, TRIGeN DC’s desiccant systems set a new benchmark for sustainable cooling and humidity control.

Introduction: Redefining Industrial Dehumidification

Industrial environments in textiles, pharmaceuticals, food & beverages, electronics, cold storage, and precision manufacturing demand controlled humidity levels for consistent performance, product quality, and operational continuity.

However, overcoming high humidity – especially in warm climates – traditionally requires:

- High electrical load

- Large cooling capacities

- Frequent regeneration

- Inefficient silica-gel cycles

- High operational and maintenance costs

Silica-based desiccant systems, once the industry norm, now fall short due to low moisture uptake, high regeneration temperatures, limited durability, and substantial disposal concerns.

This is where TRIGeN DC’s Desiccant-Based Cooling Solutions deliver transformational value.

Engineered with advanced, eco-friendly desiccant material, the system integrates seamlessly with heat pumps, ensuring:

- Lower energy consumption

- Higher absorption per cycle

- Faster regeneration

- Longer operational lifespan

- Minimal environmental impact

This positions TRIGeN DC’s solution as a modern, sustainable upgrade for industries seeking operational excellence.

How It Works

Key Advantages of Trigen DC’s Ultra Low Ambient Heat Pumps

Extreme cold typically causes heating equipment to lose capacity and efficiency. But Trigen DC’s ULAHP systems are engineered specifically for ultra-low ambient performance, ensuring:

- Consistent heating output

- Reliable thermal comfort

- High energy efficiency

- Smooth operation regardless of external temperatures.

This capability makes them ideal for industries operating in Himalayan states, high-altitude zones, cold storage regions, and global cold-weather markets.

Trigen DC utilizes optimized refrigerant selection, heat exchanger geometry, and cycle engineering to ensure strong heating performance in freezing temperatures. This advanced thermodynamic design maximizes heat extraction even from extremely cold air.

Despite operating in extreme weather, the ULAHP systems maintain a COP (Coefficient of Performance) of up to 2.1, which is significantly higher than:

- Electric resistance heaters

- Diesel-fired heaters

- Oil-fired boilers

- Direct gas heating

This means industries and facilities get more heat output per unit of electricity consumed—leading to major cost savings.

The rated outlet water temperature of 40°C makes ULAHP ideal for:

- Industrial hot water

- Building heating systems

- Hydronic heating

- Radiant floor heating

- Space heating

- Preheating for industrial processes

This versatility supports a wide variety of cold-climate applications.

Equipped with PLC or embedded controllers with HMI, Trigen DC’s ULAHP systems offer:

- Automated defrosting cycles

- Smart temperature optimization

- Real-time system diagnostics

- Parameter visibility and control

- Predictive behavior insights

These intuitive controls ensure the system performs optimally regardless of weather fluctuations.

High-strength materials used in the heat exchangers, such as:

- BPHE

- Shell & Tube

- Tube-in-Tube

- Shell & Coil

ensure durability, frost resistance, and long-term performance in harsh environments.

Regions in northern India and globally that depend on:

- Diesel burners

- Kerosene heaters

- Firewood heaters

can dramatically reduce energy cost and carbon emissions by switching to Trigen DC's clean, electrified heating systems.

With no combustion, no soot buildup, and no fuel storage, Ultra Low Ambient Heat Pumps deliver:

- Cleaner operation

- Lower maintenance cost

- Safer working environments

Deep-Tech Engineering

Behind Trigen DC’s Drying System

Deep-Tech Engineering Behind Trigen DC’s Drying System

Advanced High-Temperature Heat Pump Cycle

At the core of the system lies Trigen DC’s proprietary high-temperature heat pump cycle, allowing the system to achieve reliability:

- Hot air output from 60°C to 120°C.

- High thermal stability.

- Rapid temperature rise.

- Consistent heat across large volumes of air.

This makes the system ideal for industrial drying processes that require uniform, controlled hot air.

Reliable Compressor Technology

Equipped with a robust compressor, the system maintains:

- High efficiency.

- Low vibration.

- Longer lifespan.

- Quiet, reliable operation.

Our compressors also provide smooth modulation — essential for precise temperature control.

Smart Thermal & Electronic Expansion Valves

Depending on customer needs, the system can use:

- Thermal Expansion Valve (TXV)

OR

- Electronic Expansion Valve (EEV).

Both ensure optimal refrigerant flow, improved temperature stability, and high system responsiveness under varying load conditions.

Intelligent Controls for Precision Drying

Every unit is equipped with an advanced control system enabling:

- Real-time temperature monitoring.

- Fine-tuned airflow control.

- Stable drying conditions.

- Energy-optimized operation.

This is critical for industries like textiles, food, chemicals, printing, and pharma, where temperature uniformity directly affects product quality.

Why TRIGeN DC’s Desiccant

Technology Outperforms Silica-Gel Systems

Why TRIGeN DC’s Desiccant Technology Outperforms Silica-Gel Systems

TRIGeN DC’s desiccant solution isn’t just an alternative – it is a next-level replacement for traditional silica-based systems.

With moisture absorption exceeding 80%, TRIGeN DC’s desiccants outperform silica-gel beds, which typically achieve 25–35%.

Greater adsorption means:

- More moisture removal per cycle

- Fewer regeneration cycles

- Higher efficiency and uptime

Silica-gel beds require 120°C–140°C regeneration temperatures - demanding heavy heating systems, high electrical loads, and significant running costs.

TRIGeN DC regenerates at ~70°C, enabling:

- Up to 70–80% lower regeneration energy

- Integration with heat pumps

- Lower peak load

- Faster cycle times

- Longer desiccant life

This alone makes TRIGeN DC’s technology dramatically more cost-efficient.

Traditional silica beds degrade quickly, requiring frequent replacements and costly waste handling.

TRIGeN DC’s desiccants are:

- Environmentally responsible

- Long-lasting

- Regeneration-efficient

- Non-toxic

- Disposal-safe

Industries reduce lifetime costs while improving sustainability metrics.

With faster adsorption and regeneration cycles, TRIGeN DC’s systems run reliably in:

- 24×7 manufacturing.

- High-humidity zones.

- Seasonal peak loads.

- Large-volume industrial processes.

Unlike silica-based desiccants, TRIGeN DC’s low-regeneration-temperature chemistry integrates flawlessly with heat pump systems, unlocking:

- Energy reuse

- High COP regeneration

- Greater overall system efficiency

- Significant reduction in electricity consumption

This positions TRIGeN DC’s desiccant technology at the forefront of next-generation sustainable cooling.

Performance & Efficiency Superiority

High COP = Lower Energy Cost

The system delivers a COP of 1.7–3.5, meaning:

Superior Drying Quality

Industries often face issues like:

- Overdrying.

- Uneven drying.

- Product damage.

- High reject rates.

Trigen DC's system solves this with:

- Precise temperature control.

- Stable airflow.

- Even heat distribution.

- Zero flame contamination.

This leads to consistent output and improved product quality.

Intelligent Airflow Management

With airflow up to 34,000+ CMH, the system ensures:

- Fast drying cycles.

- Large volume air movement.

- Consistent humidity control.

- Better moisture removal.

Ideal for bulk drying applications.

Wide Operating Range

- Ambient operating: 10–45°C.

- Designed for a 25°C standard ambient.

- Can operate efficiently across varied climates, including hot industrial environments

Industry Applications

Trigen DC’s Desiccant Based Cooling Solutions are widely applicable across industries that require reliable heating in sub-zero climates.

Cold Storage & Warehouses

- Prevents moisture condensation

- Reduces frost formation

- Improves temperature stability

Pharmaceuticals

- Cleanrooms

- Tablet manufacturing

- Capsule filling

- R&D and packaging zones

Food & Beverage

- Packaging halls

- Processing lines

- Cold chain areas

- Warehouses

Chemical & Specialty Manufacturing

- Hygroscopic material handling

- Controlled atmosphere processes

Electronics Manufacturing

- Component storage

- PCB assembly

- Clean rooms

- Semiconductor processes

Textiles & Garments

- Dyeing, printing, and finishing processes

- Reduced moisture for faster drying

- Stable humidity for fabric handling

Commercial and Industrial Buildings

- HVAC support

- Energy-efficient dehumidification

Across these industries, TRIGeN DC ensures humidity levels are stabilized, energy costs are reduced, and operational efficiency is maximized.

Desiccant vs. Silica-Gel Systems

| Parameter | Silica-Gel Systems | TRIGeN DC Desiccant Systems |

|---|---|---|

| Moisture Absorption Capacity | 25–35% | >80% |

| Regeneration Temp | 120–140°C | ~70°C |

| Energy Consumption | High | Low to Ultra-Low |

| Regeneration Speed | Slow | Fast |

| Heat Pump Compatibility | Poor | Excellent |

| Lifespan | Moderate | Long Life |

| Disposal Concern | High | Eco-Friendly |

| Industrial Duty | Limited | 24×7 capable |

Sustainability & Carbon Reduction Impact

Industries transitioning from diesel, LPG, or kerosene heating to ULAHP can reduce carbon emissions significantly.

Sustainability & Carbon Reduction Impact

Industries transitioning from diesel, LPG, or kerosene heating to ULAHP can reduce carbon emissions significantly.

Redefining Humidity Control for the Modern Industrial World

A New Era of Sustainable Cooling & Dehumidification — Powered by TRIGeN DC

Industries today demand solutions that deliver more than just performance — they require sustainability, intelligence, energy efficiency, and long-term value. TRIGeN DC’s Desiccant-Based Cooling Solutions meet all these expectations and far exceed what traditional silica-gel technologies can offer.

With >80% absorption, low-temperature regeneration, heat pump integration, eco-friendly materials, and significant carbon reduction, this system is built to support the industrial world’s transition towards clean, efficient, and responsible thermal management.

Whether in textiles, pharmaceuticals, electronics, food processing, or advanced manufacturing, TRIGeN DC empowers industries to operate with stability, efficiency, and sustainability — today and for decades to come.

Why Choose TRIGeN DC?

TRIGeN DC is India’s foremost deep-tech developer of high-temperature industrial heat pumps, delivering solutions unmatched globally.

Advantage TRIGeN DC:

- Pioneer of India’s first steam-generating heat pump.

- Leader in 120°C–145°C high-temperature electrified heat.

- World’s First heat pump operating at high altitude of 17900 ft.

- Built for 24×7 industrial duty cycles.

- IoT-driven predictive intelligence.

- Complete design-to-commissioning capability.

- Proven deployment across diverse sectors

Trigen DC — Engineered for the World. Made in India.

Ready to upgrade to a cleaner,

smarter, and more energy-efficient system?

Ready to upgrade to a cleaner, smarter, and more energy-efficient system?

Contact Trigen DC today for a free consultation, detailed ROI analysis, or a customized Steam Generating Heat Pump solution tailored to your industrial needs.